Gone are the days when cereal farmers resorted to the practice of “debbio,” or stubble burning. This method was already documented in the first century B.C. by the Roman writer Publius Vergilius Maro, better known as Virgil, the author of the epic poem “Aeneid.” He attributed to debbio the ability to transfer “mysterious forces” to the soil and dissolve potential damage in plant tissues—concepts that, in a way, were correct since fire destroys fungal spores of pathogens.

Stringent legislative limits

Today, this practice is strictly regulated by law, with violations leading to fines of several thousand euros. Instead, the preferred method is stubble incorporation using specialized equipment, a process that is also incentivized by public funding, granting farmers several hundred euros per hectare under Regional Rural Development Plans. To qualify for these subsidies, the soil must not be tilled deeper than twenty centimeters, and its layers must not be mixed. Combining this technique with cover crops is even more advantageous.

No more than 20 centimeters

As agricultural practices have evolved, so has agricultural mechanization, following these technical and regulatory directives by developing tailored solutions. Disc cultivators, for example, are specifically designed for minimal tillage and soil refinement after plowing. Their action allows working the soil up to a depth of 15 centimeters, incorporating crop residues and spontaneous flora into this layer. Additionally, the same discs can be used to break clods resulting from plowing, redistributing their contents evenly across the soil.

Evolutions on isobus standards

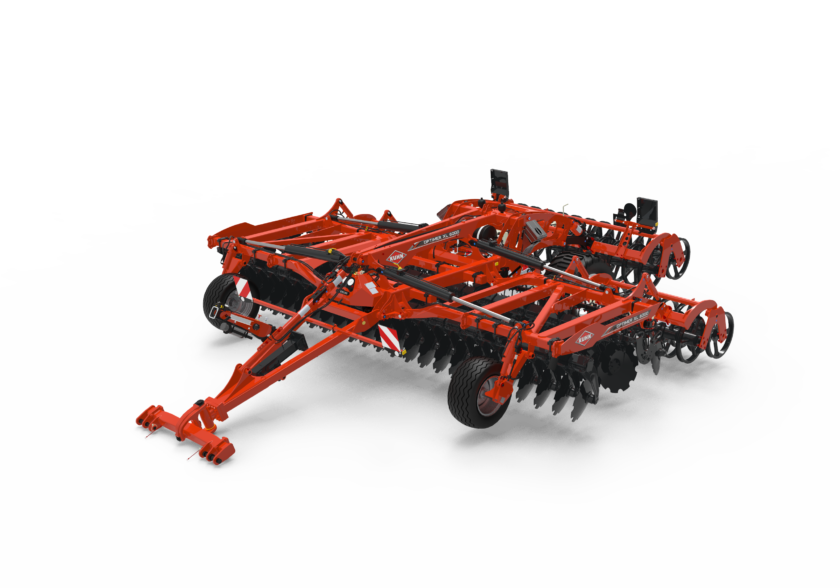

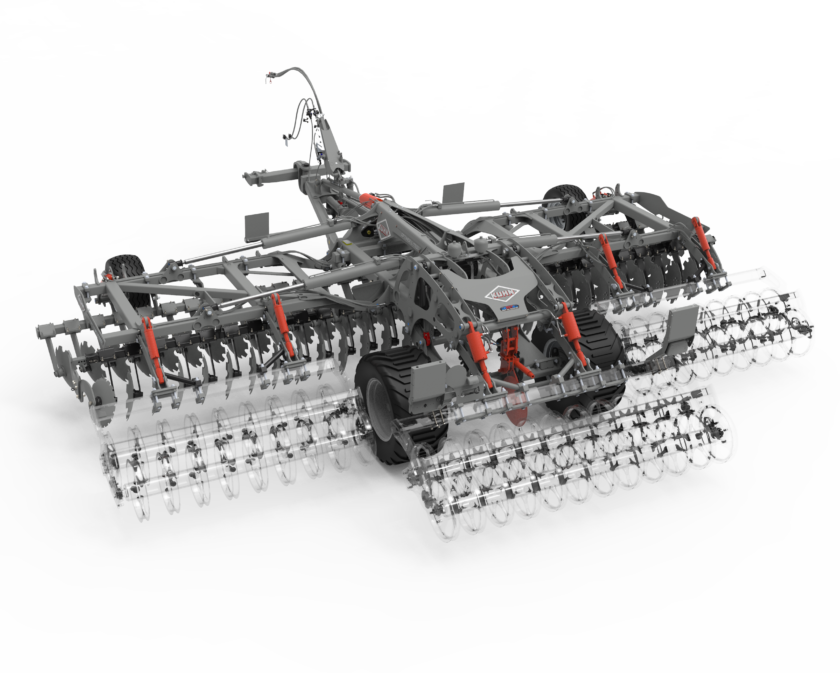

The Kuhn “Optimer” series cultivators are designed to meet these objectives. These disc-equipped implements cater to various needs thanks to a wide range of models and versions. The continuously evolving series has recently benefited from technological advancements related to ISOBUS functionalities. Among these innovations, the independent disc cultivators “Optimer” with working widths of six and seven and a half meters now incorporate the “Smart Soil Technology” (SST) system, which ensures more precise and comfortable operation through exclusive and advanced features.

The “Steady Control Ultimate” system, for example, enables automatic work adjustment, ensuring a uniform and precise depth across the entire width of the implement. This is achieved through pressure and position sensors that, via the onboard terminal, manage the hydraulic cylinder pressures regulating the tool’s configuration. As a result, the working depth is continuously and variably adjusted, maximizing soil uniformity even on irregular terrain and at high speeds.

Kuhn Optimer, an increasingly refined technology

Thanks to “Steady Control Ultimate,” the operator no longer needs to leave the tractor to adjust the working pressures manually, significantly improving precision. The system continuously monitors and regulates the work parameters based on real-time measurements.

However, achieving an optimal seedbed formation is not only about correctly setting the working depth. The cultivator must also faithfully follow the tractor’s trajectory. This is not an issue on flat land, but in hilly areas and slopes, maintaining alignment becomes more challenging. In such conditions, the implement tends to drift downhill, misaligning itself from the operator’s intended path.

To correct this issue, the SST system introduces the “Auto-Line” function, which continuously adjusts the alignment between the tractor and cultivator, ensuring the implement stays on course regardless of terrain inclination. These corrections are entirely automatic. A coulter at the center of the machine constantly measures the tool’s position and drift angle relative to the longitudinal axis. This data allows the terminal to make real-time adjustments, acting on the implement’s leveling wheels and closing roller to balance lateral forces affecting the front and rear discs due to the slope.

Through dedicated hydraulic actuators, the system modifies the machine’s horizontal position by differentiating the working depth of the front and rear discs by up to three centimeters. At the coulter level, this ensures an angle always aligned with the direction of travel, resulting in a particularly uniform stubble incorporation while minimizing overlap between passes.

Return maneuvers are automatic

At the end of the field, the “Task Controller” function simplifies the lifting and lowering of the implement by automating these operations. The entire procedure is carried out without operator intervention, and even the unfolding and folding sequences of the cultivator are fully automated.

Solutions for Every Need

The Kuhn “Optimer” series offers multiple versions to meet various operational needs, including mounted, foldable-mounted, and trailed models. The latter even includes a top-of-the-range “Optimer L 12500” with a working width of twelve and a half meters.

Besides differences in tractor hitch types and working widths, “Optimer” cultivators also vary in disc sizes. The “L” versions feature serrated discs with a 510-millimeter diameter, whereas the “XL” versions use 620-millimeter discs. This results in different working depths, ranging from three to ten centimeters for “L” versions and five to fifteen centimeters for “XL” models. However, all discs share a thickness of six millimeters, and their number is proportional to the implement’s width, which in turn affects power requirements.

The offer in the Italian market

For the Italian market, the lineup starts with the “Optimer 300,” featuring 24 discs and a three-meter working width, reaching up to the “Optimer 7500” with 60 discs. These models require power inputs ranging from 90 to 450 horsepower, allowing any farm to adopt Kuhn cultivators by simply matching the working width to its machinery fleet.

Direct connections

In line with the challenges launched by Agriculture 4.0, Kuhn also looks to digital applied to agricultural practices. The interconnection between machines and the company center, as well as the possibility of saving data and information, will in fact play an increasingly strategic role in monitoring and tracking the activities of the construction sites deployed in the field. To satisfy these needs, “Kuhn Connect” is proposed, a digital multitasking solution that allows you to take advantage of the most advanced connectivity systems between machines and company centers.

New functions

To further increase the potential of “Kuhn Connect”, new functions have also arrived, accessible via the “Cci 800” and “Cci 1200” terminals continuously connected via WiFi to the company center’s internet network. For example, the “Online Cci Update” function keeps the software constantly updated by installing its most recent versions on the terminals. The “Cci Remote View” application instead allows you to instantly share the terminal screen both with colleagues and with the dealer, thus being able to receive timely assistance in case of need.

Kuhn Optimer: help from digital

The ability to send and receive data in real time has also become increasingly fundamental over time. This is an advantage brought by “Kuhn EasyTransfer”, a system which, via “Agrirouter”, allows for example to receive prescription maps with which to power the terminals in the cabin. In the near future, within the current year, the launch of “Cci.Maps” has been announced, an application created to manage field activities from the office thanks to the permanent synchronization of terminals and the farm. “Cci.Maps” also offers multiple functions, such as the design of prescription maps and the calculation of the correct doses of agrochemicals and fertilizers to apply. “Kuhn Connect” therefore offers a set of particularly advanced services, to benefit from which farmers and contractors must register on the “MyKuhn” online platform, an extremely simple and fast procedure.

Titolo: Kuhn Optimer, ideal cultivators for any soil cultivation

Translation with ChatGPT